Metro Power Supply Projects

The electrical system of the metro is a vital component in the operation and efficiency of rail transport networks. This system encompasses the provision, distribution, and control of electricity to meet the energy needs of trains and related equipment.

Components of the Metro Electrical System:

1. Substations: These substations are responsible for converting and distributing electricity. Typically, power is received from the national grid and transformed to a suitable voltage for metro use. Substations include transformers, switches, and protective equipment.

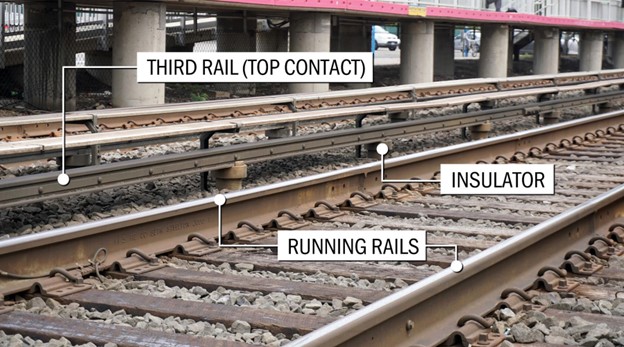

2. Power Supply System: This system generally consists of overhead or underground power lines, transferring electrical energy to trains via a third rail. Many metro systems utilize DC (Direct Current) power systems.

3. Switchgear: Switchgear is employed to control and protect the metro electrical systems.

Safety Considerations:

Safety in the metro electrical system is of utmost importance. Equipment must be designed to withstand voltage fluctuations, overloads, and emergency conditions. Additionally, protective systems should be regularly inspected and maintained. Ultimately, the metro electrical system not only aids in powering trains but also plays a crucial role in enhancing the overall efficiency and safety of the transport network.

Metro substations act as key components in energy supply and distribution within urban rail transport systems. Below, we introduce various types of metro substations, including HVS, LPS, and TPS:

1. HVS Substation (High Voltage Substation):

– Specifications: These substations are typically designed for high voltages and can manage voltages around 12 kilovolts and above. Key equipment includes transformers, power switches, and protective systems.

– Application: HVS substations serve as points for converting high voltage to lower voltages for distribution within the metro network. They are usually located near energy supply sources.

2. LPS Substation (Low Voltage Substation):

– Specifications: These substations are designed for lower voltages, typically managing voltages around 400 volts. Equipment includes step-down transformers and distribution boards.

– Application: LPS substations provide energy to internal metro systems and equipment such as signaling, lighting, and air conditioning. In metro stations, various facilities, including escalators, elevators, lighting systems, ventilation, sewage pumping, fire extinguishing systems, and communication and signaling systems, require electrical energy at 400 volts AC and 230 volts single-phase, supplied through LPS substations. Additionally, at metro terminals, diverse systems including maintenance, train washing, heating and cooling systems, lighting, wheel machining equipment, and painting halls also require electrical energy at 400 volts AC and 230 volts single-phase, which is also supplied by LPS substations.

3. TPS Substation (Traction Power Substation):

– Specifications: These substations are specifically designed to supply energy to traction systems (trains) and typically manage voltages around 750 volts DC or 24 kilovolts AC.

– Application: TPS substations provide the necessary energy for train movement and serve as the primary energy source for rail systems. This substation is responsible for converting the 20 kilovolt power transmitted from the 20/63 kilovolt substation to 750 volts DC, which is then delivered to the trains via the third rail or overhead network. To adequately supply trains at specified distances, traction substations must be present.

Each of these substations plays a critical role in the optimal and safe operation of metro systems, contributing to the energy needs for daily operations.

Power Supply to the Metro:

Power supply to the metro is typically achieved through two main methods: overhead lines and the third rail. Each method is described in detail below, along with their strengths and weaknesses.

1. Overhead Lines:

In this method, electricity is transmitted to trains through overhead cables installed above the tracks. These cables are usually designed as one or more high-voltage power lines.

– Strengths:

– Simplicity of installation and maintenance: Installing overhead lines is generally simpler than the third rail, and they are more accessible for repairs.

– Reduced infrastructure costs: Due to the lack of need for major changes to existing infrastructure, initial costs are lower.

– Flexibility: Overhead lines offer greater flexibility in routing compared to the third rail.

– Weaknesses:

– Vulnerability to weather conditions: Overhead lines may be affected by wind, rain, and snow, potentially leading to service disruptions.

– Visual limitations: The presence of overhead lines may negatively impact urban aesthetics and harm the beauty of the environment.

2. Third Rail:

In this method, electricity is transmitted to trains through an additional rail located alongside or between the main rails. This rail is typically directly connected to the power supply system.

– Strengths:

– Greater stability: The third rail is generally more resistant to weather conditions, reducing the likelihood of disruptions caused by the elements.

– Visual appeal: The absence of overhead cables can help maintain urban aesthetic beauty.

– Weaknesses:

– High installation and maintenance costs: Installing the third rail requires more significant infrastructure changes, leading to higher maintenance costs.

– Safety hazards: The presence of electricity in the third rail can pose risks to workers and passengers, especially in emergencies.

Conclusion:

The choice between overhead lines and the third rail depends on the specific conditions of each project, costs, safety requirements, and aesthetic considerations. Each method has its own advantages and disadvantages that must be considered to select the best option for metro power supply.

Switchgear:

Switchgear is electrical equipment used to control, protect, and isolate electrical circuits. Various types of switchgear are employed in the metro, including LVAC (Low Voltage Alternating Current), LVDC (Low Voltage Direct Current), and MV (Medium Voltage). Below, we explain each type and their functions:

1. LVAC Switchgear:

These switchgears are used to control and distribute electricity at low voltages (typically up to 1000 volts). Their primary functions include switching circuits on and off, protecting equipment from overloads and short circuits, and distributing power to various loads in stations and metro systems.

2. LVDC Switchgear:

This type of switchgear is designed for low-voltage direct current systems (typically up to 1500 volts). In the metro, these switchgears are usually used to control and distribute power to braking systems and other electrical equipment that require direct voltage. They also play a role in protecting the system from fluctuations and electrical issues.

3. MV Switchgear:

Medium voltage switchgear (typically between 1000 and 35000 volts) is used for controlling and distributing electricity at higher levels. In the metro, these switchgears are employed to supply power to stations and main power systems. Their responsibilities include switching circuits on and off, protecting equipment from electrical issues, and managing heavy loads.

Metro signaling is a vital aspect of rail transport systems that aids in the management and control of train movements. These systems are designed to enhance the safety, efficiency, and capacity of metro lines. This article will explore metro signaling and the new methods available in this field.

Metro signaling refers to a collection of equipment and technologies used to control train movements and prevent accidents. These systems include light signals, central control systems, and more advanced technologies such as automation systems and wireless communications.

In the past, traditional signaling methods primarily relied on light and mechanical signals. These systems were manually controlled and required human oversight and management. Due to their limitations in capacity and efficiency, these methods have gradually been replaced by more advanced systems.

New signaling methods include:

- Automatic Train Operation (ATO): These systems automatically control train movements and can provide more precise scheduling. ATO helps reduce stop times and increase line capacity.

- Communications-Based Train Control (CBTC): This technology uses wireless communications to determine the precise location of trains. CBTC allows trains to operate closer together, thereby increasing line capacity.

- Traffic Management Systems: These systems enable metro line managers to centrally control train traffic. By utilizing collected data, they can make better decisions regarding scheduling and crisis management.

Benefits of New Methods:

– Increased Safety: By reducing human errors and employing advanced technologies, the safety of the system is significantly enhanced.

– Improved Efficiency: New systems can reduce travel times and increase line capacity.

– Cost Reduction: Automation and process optimization lead to lower operational costs.

Conclusion:

Metro signaling, as a key element in rail transport systems, is advancing towards automation and optimization with technological progress. New methods such as ATO and CBTC not only enhance safety and efficiency but also enable metro line managers to manage traffic more effectively. Given global trends, it is expected that these technologies will be more widely implemented in metro systems in the near future.